Firefighters rely on their gear for protection in the most dangerous conditions imaginable, which is why understanding how to wash fire gear and maintain it properly with PPE dryers from Williams Direct Dryers is essential. While cleaning is a critical step, drying fire gear correctly with one of our specialized PPE dryers is just as important to prevent damage, reduce turnaround time, help control bacteria and fungal growth, and help ensure the gear is always ready for action.

How to Wash Fire Gear

Washing fire gear should always follow NFPA 1851 guidelines, which detail the standard for selection, care, and maintenance of protective ensembles for structural firefighting and proximity firefighting. Here is a quick overview of best practices:

- Use specialized detergents: Never use bleach, fabric softeners, or standard laundry detergent. Instead, use approved cleaners specifically designed for PPE to preserve the integrity of the materials.

- Avoid top-load washing machines: Front-load washers with programmable settings are preferred because they are gentler on the gear and allow you to control water temperature, rinse cycles, and spin speed.

- Remove detachable components: Elements such as liners, harnesses, and accessories should be removed when possible to allow a more thorough and effective wash.

- Inspect before and after washing: Check for any damage, tears, or signs of degradation before putting gear back into service.

Knowing how to wash fire gear properly can significantly reduce the risk of exposure to carcinogens, soot, and other contaminants, all while protecting the structure of the gear.

How to Maintain Fire Gear

Maintenance goes beyond cleaning. To truly understand how to maintain fire gear, you must routinely inspect, repair, and store it properly:

- Routine inspections after every use help detect damage early.

- Prompt repairs prevent small issues from becoming big ones. Consult manufacturers or certified repair technicians for compliant fixes.

- Proper storage in cool, dry areas shields gear from UV rays, chemicals, and moisture.

However, no maintenance routine is complete without ensuring the gear is fully dry both inside and out after each use or wash. That is where Williams Direct Dryers makes a real difference.

How to Dry Fire Gear with Williams Direct Dryers

Traditional drying methods like hanging gear or placing it in front of a fan are inadequate and potentially damaging. Improper drying can lead to mildew, fiber breakdown, and a reduced lifespan of critical components.

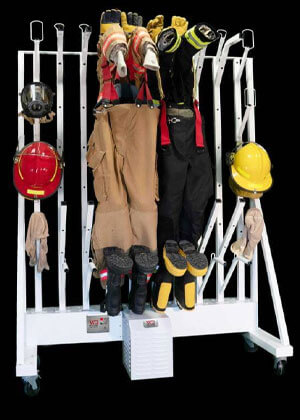

Williams Direct Dryers offers purpose-built fire gear dryers that use ambient, room temperature or gently warmed air to dry gear from the inside out. Our PPE dryers are engineered specifically for turnout gear: gloves, boots, masks, jacket, pants, and helmets, helping ensure even, efficient drying without compromising material integrity.

Here is why using a PPE dryer from Williams Direct Dryers is the best method when learning how to dry fire gear:

- Non-damaging air flow: No high heat is used, so reflective trim, moisture barriers, and thermal layers are preserved.

- Time-saving efficiency: Dry times are significantly faster compared to passive drying methods, which can take 24–48 hours.

- Complete drying: Moisture is removed, even from hard-to-reach areas, preventing mold, mildew, and odor buildup.

Trust Our Reliable Solution for Fire Departments

Maintaining firefighter turnout gear is a matter of safety, performance, and compliance, and by using a fire gear dryer from Williams Direct Dryers as part of your regular maintenance regimen, you are not only extending the life of your PPE but also protecting the people who depend on it.

Whether you are responsible for a single station or an entire department, Williams Direct Dryers offers durable, efficient solutions that simplify how to wash fire gear, how to maintain fire gear, and most importantly, how to dry fire gear safely and effectively. Contact us today to learn more!